by Mai Vang, Marketing Director | Jul 30, 2023

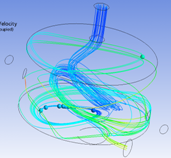

This course focuses on essential Rocky DEM models and includes five hands on workshops. Particle shape representations, motion frames, and postprocessing will be discussed. Students will become proficient with the Rocky interface throughout the course with workshops that build on one another and expose progressively more advanced features.

Students are encouraged to be ready to discuss areas of Rocky application at their own companies.

Lecture 1: Intro to DEM

Lecture 1: Intro to DEM

This workshop introduces the Rocky interface and explores the use of conveyors with continuous particle inlets.

Workshop 1: Transfer Chute

Workshop 1: Transfer Chute

This workshop explores adhesion modeling, the volume fill approach for adding particles to a model and describes a common test model used to calibrate material data.

Workshop 2: Static Angle of Repose Test

Workshop 2: Static Angle of Repose Test

This workshop explores adhesion modeling, the volume fill approach for adding particles to a model and describes a common test model used to calibrate material data.

Workshop 3: Vibrating Screen

Workshop 3: Vibrating Screen

This workshop explains the use of motion frames in the context of oscillating motion. Particle size distribution definition is also discussed.

Workshop 4: SAG Mill

Workshop 4: SAG Mill

Surface wear and periodic boundaries are used in this workshop to demonstrate the behavior of a mill.

Workshop 5: Drop Weight Test

Workshop 5: Drop Weight Test

Freebody motion of boundaries as well as the Ab-T10 breakage model are highlighted in the final workshop of the course.

Course Enrollment and Schedule

Introduction to Ansys Rocky

by Mai Vang, Marketing Director | Jul 30, 2023

This course provides an introduction to conducting computational fluid dynamic simulations in Ansys CFX.

The course focuses on use of the DesignModeler and/or SpaceClaim to prepare CFD models for meshing within the Ansys Workbench meshing environment, and then pre and postprocessing with Ansys CFX.

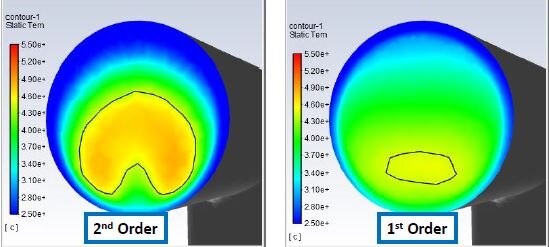

The course devotes very little time to CFD theory and focuses on the use of the software through workshops to solve practical problems. Analysis types included in the course are generally turbulent with various functionality highlighted for each one – multiphase flow, conjugate heat transfer and fluid-structure interaction with Ansys FEA, or moving boundaries, for example.

Most workshops use neutral geometry in the form of SAT or Parasolid files for starting points. DRD encourages the students to bring a SAT or Parasolid file with them to the training (preferably a model from their workplace) for a little testing and discussion of their own problems to solve. Although most exercises will use either a SAT or Parasolid file, DRD will also demonstrate the integration between Ansys and CAD systems including associativity.

Chapter 1 - Overview of Workbench, DesignModeler, and Domain Extraction

Workshop 1a – Orientation of Workbench Interface and Sketching

In this workshop we introduce the Ansys Workbench environment and sketching in DesignModeler and/or SpaceClaim. A small model is created from scratch so the users gain some experience with the user interface.

Workshop 1b – Extraction of Fluid Domain

In this workshop we introduce the use of DesignModeler and SpaceClaim and the methods of creating a fluid domain from previously provided structural geometry.

Chapter 2 - Meshing a Fluid Domain for CFD Solutions

Workshop 2a – Element Types and Physical Behavior

This workshop demonstrates how to control creation of lower order versus higher order elements and tetrahedron versus brick elements in Mechanical. It also provides students the opportunity to compare solution accuracy and computational resources for models with lower and higher elements using the Mechanical solution information object.

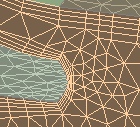

Workshop 2b – Creating and Combining Multiple Domain Meshes

This workshop creates both a swept hexagonal mesh with boundary layer and a nonuniform tetrahedral mesh and combines them into a single domain for solving.

Workshop 2c – Multizone Meshing

This workshop uses the multizone mesher to produe a hex dominant mesh and hexacore mesh with and without inflation layers.

Chapter 3 - Overview of Single Phase CFD Analysis with Introduction to Fluid-Structure Interaction

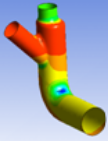

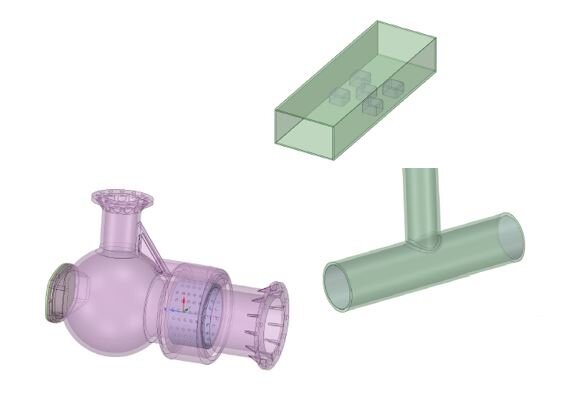

Workshop 3 – Stress Analysis of a Pump Fluid End Using Direct and Iterative Solvers

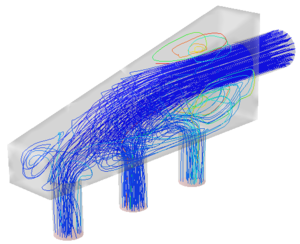

This workshop demonstrates how to conduct a simple flow analysis in CFX and transfer the pressure boundary conditions to Mechanical for subsequent FEA analysis. Relative flow rates between the inlets are also examined.

This workshop demonstrates how to conduct a simple flow analysis in CFX and transfer the pressure boundary conditions to Mechanical for subsequent FEA analysis. Relative flow rates between the inlets are also examined.

Chapter 4 - Conjugate Heat Transfer

Workshop 4 – Conjugate Heat Transfer Simulation of Cooling Fin

This workshop covers the creation of a conjugate heat transfer model between two different fluid domains and a tube with heat fins. Downstream flow temperatures and heat transfer coefficients for the fins are calculated.

Chapter 5 - Turbulence

Workshop 5 – Model Simplification and Flow through a Serpentine Cavity

A serpentine cavity is extracted from a solid model, meshed with a boundary layer and the pressure drop across the model is found.

Chapter 6 - Multiphase Flow

Workshop 6 – Multiphase Flow in Sand Mixing Tank

For this workshop the fluid domain is extracted from a tank and then various sand and water flows are applied to the inlets of the tank. Initial locations of erosion is predicted along with the rate of erosion on the tank walls.

Chapter 7 - Transient Simulations and Thermal Analysis

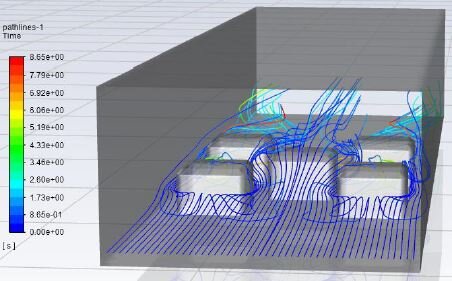

Workshop 7 – Transient Thermal Analysis of an Electronics Package

For this workshop the fluid domain is extracted from a full 360 degree solid model. The heat source is surrounded by a circular heat sink to help convect away heat as 50W of energy is applied. The transient heat up is calculated.

Chapter 8 - MultiFrames of Reference, Cavitation

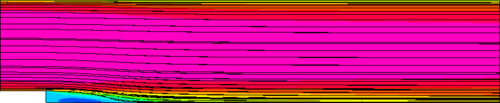

Workshop 8 – Free Surface Flow with Particles in an Open Channel

A fluid domain is extracted from solid geometry for this simulation. The mesh is created and multiphase flow with air and water is defined. In addition, particulates are added to the water and the analysis is solved as transient to examine particle flow.

Chapter 9 - Free Surface Flows

Workshop 9 – Rotating Impeller with Cavitation

The purpose of the tutorial is to model cavitation in a centrifugal pump, which involves the use of a rotation domain and the cavitation model.

Chapter 10 - Source Terms and Fan Modeling

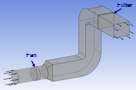

Workshop 10 – Modeling Pressure Rise Using a Fan Curve and Filter with Source Terms

This workshop simulates a duct with a fan and filter. The fan is not explicitly modeled but a fan curve is used instead and the filter is modeled as a porous domain.

Course Enrollment and Schedule

Introduction to Ansys CFX

by Mai Vang, Marketing Director | Jul 30, 2023

This course provides an introduction to conducting CFD simulations in Ansys CFD.

The course devotes little time to CFD theory and focuses on practical use of the software through both lectures and workshops that demonstrate practical problems. Workshops build in difficulty throughout the course and develop skills in setup, solving, and postprocessing models in Fluent.

Early workshops create geometry from scratch or import CAD geometry as starting points. This allows students to build skills with meshing and geometry preparation. Latter workshops utilize pre-generated mesh files allowing for more complex problems to be undertaken during class time.

DRD encourages the students to be ready to discuss their application for Fluent with the instructor so that we can best tailor the training to each student.

DRD conducts this course over two days. Students will receive all training materials to take home and reference later.

Chapter 1 – SpaceClaim User Interface, Basic Operations, and Creating Geometry

Workshop 1.1 – SpaceClaim Basics

In this workshop we introduce Ansys SpaceClaim and use it to extract a fluid volume from a mixing tee.

Workshop 1.2 – Geometry Repair using SpaceClaim

This workshop introduces the use of automated repair tools in SpaceClaim.

Workshop 1.3 – Creating a Mixing Tee from Scratch

This workshop demonstrates creating geometry from Scratch in SpaceClaim.

Workshop 1.4 – Creating Named Selections and Bodies of Influence in SpaceClaim

This workshop introduces creation of named selections and bodies of influence. Shared topology considerations for bodies of influence are also discussed.

Chapter 2 – CFD Overview

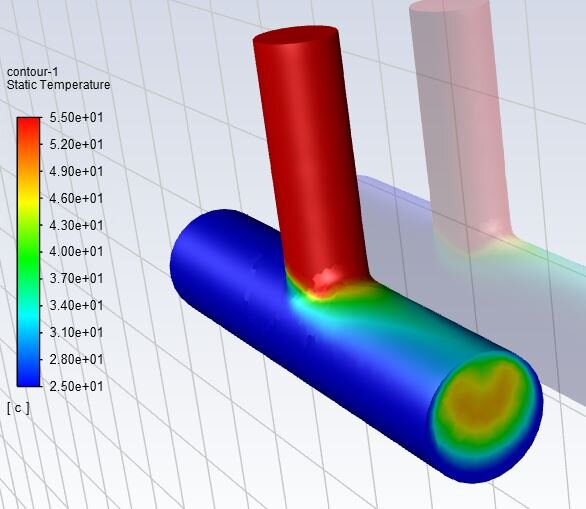

Workshop 2 – Mixing Hot and Cold Streams in a Mixing Tee

This workshop covers the creation of a model in which two air streams at different temperatures are mixed together. The mixing uniformity is analyzed.

Chapter 3 – Watertight Geometry Workflow Overview and Surface Meshing

Workshop 3 – Meshing of a Static Mixing Device

This workshop demonstrates meshing a solid geometry using capping within the Fluent Meshing Watertight Workflow.

Chapter 4 – Geometry Description and Volume Meshing

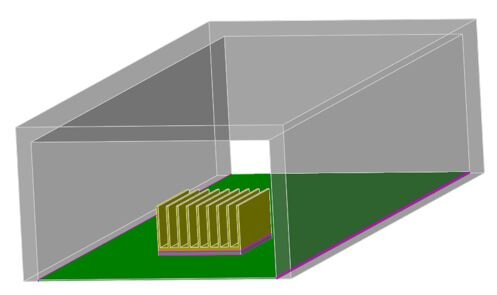

Workshop 4 – Meshing of a PCB and Heatsink

This workshop covers meshing of a heat producing electrical component on a circuit board. The board, component, heatsink, and surrounding air are meshed in preparation for solving.

Chapter 5 – Solution Mode User Interface

Workshop 5 – Flow Distribution in an Air Manifold

This workshop demonstrates how to conduct a simple flow analysis in Fluent. Relative flow rates between the outlets are also examined.

Chapter 6 – Physics Tab

Workshop 6 – Meshing and Solving Using Zero Thickness Baffles

A duct with turning vanes is meshed in Fluent Meshing and solved. Proper meshing of zero thickness baffles is demonstrated.

Chapter 7 – Results Tab

Workshop 7 – Flow Over Heated Obstacles

This workshop introduces heat transfer via wall boundary conditions and utilizes symmetry to speed up computation of the solution.

Chapter 8 – Solution Tab

Workshop 8 – Solver Options and Settings

The mixing tee model is reexamined using various solver settings to see how they affect convergence behavior and result quantities.

Chapter 9 – Best Practices

Workshop 9 – Turbulent Flow Past a Backward Facing Step

Flow separation on a backward facing step is analyzed. The effect of including an accurate inlet velocity profile is also explored.

Chapter 10 – Turbulence

Workshop 10 – Electronics Cooling with Natural Convection and Radiation

This workshop covers the conjugate heat transfer analysis of a heated chip and heatsink undergoing natural convection. Surface-to-surface radiation is also examined.

Chapter 11 – Heat Transfer

Chapter 12 – Transient Simulation

Course Enrollment and Schedule

Introduction to Ansys Fluent

by Mai Vang, Marketing Director | Jul 21, 2023

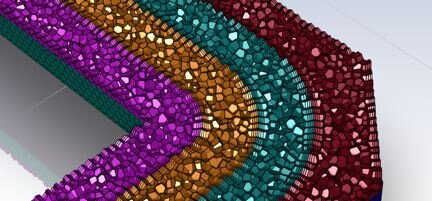

This course provides an introduction to meshing models for Fluent using Workbench Meshing. Fluent Meshing is the preferred tool for the majority of models as it will be able to provide the most efficient meshes on the most complex geometry with the least amount of model prep. However, there are unique scenarios where Workbench Meshing can be used to provide highly sculpted meshes to meet demanding requirements, such as non-Cartesian aligned hexahedral elements (cyclones) or layered elements for modelling 1DOF motion (moving valves). Pure hexahedral and hybrid hexahedral/tetrahedral meshes can provide significant benefits in solution speed and accuracy over unstructured polyhedral or tetrahedral meshes in these scenarios.

Students will focus on completing workshops that build in difficulty throughout the course. Key skills related to fluid volume creation, decomposing geometry in SpaceClaim, and setup of mesh controls in Workbench Meshing will be discussed and practiced.

DRD’s Introduction to Ansys Fluent course is a prerequisite to this course.

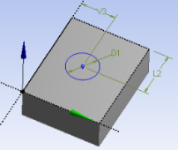

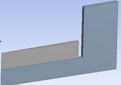

Workshop 1 - Plunger Box

This workshop introduces the basics of geometry preparation for Workbench Meshing along with general purpose tetrahedral meshing with inflation.

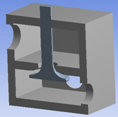

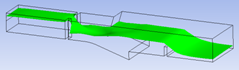

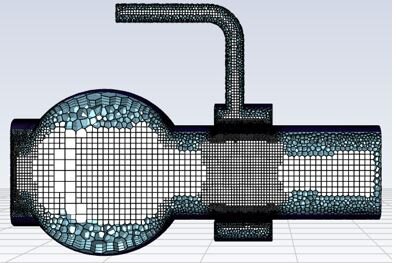

Workshop 2 – Ball Valve

This workshop introduces swept hexahedral meshing alongside the concept of multibody parts that allow for conformal meshes with different element shapes.

Workshop 3 – Mixing Tank

This workshop presents slicing strategies to maximize hexahedral elements in cylindrically dominated geometry as well as utilizing selective non-conformal meshing.

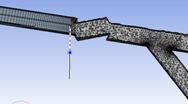

Workshop 3 – Solenoid Valve

This workshop demonstrates recommended meshing strategies for motions containing single degree of freedom motion, including slicing, selectively shared topology, named selection management, and meshing order.

Course Enrollment and Schedule

Workbench Meshing for Ansys Fluent